CNC milling thiab tig yog ntau yam, raug nqi thiab raug, tab sis qhov ua tau rau CNC machined qhov chaw nthuav dav ntxiv txawm tias qhov kev ua tiav ntxiv.Cov kev xaiv yog dab tsi?Thaum lub suab zoo li ib lo lus nug yooj yim, cov lus teb nyuaj vim tias muaj ntau yam los xav txog.

Prototype Projects

Ua ntej, qhov tiav yog dab tsi?Puas yog txhawm rau txhim kho kev zoo nkauj lossis kev ua haujlwm?Yog tias tom kawg, dab tsi ntawm kev ua haujlwm yuav tsum tau txhim kho?Corrosion resistance, deg hardness, hnav tsis kam lossis EMI / RFI shielding?Cov no tsuas yog qee cov lus nug uas yuav tsum tau teb yog li, piv txwv li tus tsim qauv paub tias lub hom phiaj yog dab tsi, cia peb saib ntau yam kev xaiv.

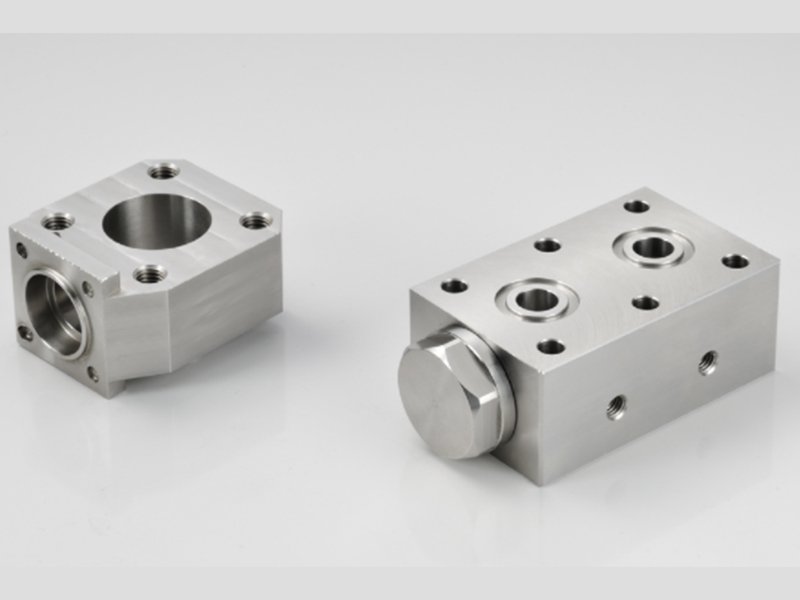

Ua tiav rau CNC Machined Metal Prototype Parts

Tshaj li 40 xyoo dhau los, Prototype Projects 'machinists tau hais kom tsim cov khoom los ntawm cov hlau loj heev rau kev siv hauv ntau qhov kev lag luam.Cov khoom lag luam tsis tu ncua deburred, ntxuav thiab degreased, txawm li cas los xij, kev xaiv ntawm cov khoom tiav yog dav heev.

Niaj hnub no, peb cov neeg siv khoom nyiam cov hlau yog aluminium alloy 6068, stainless hlau 304 thiab stainless hlau 316. Qhov tseeb, peb cov no nquag thov kom peb tuav cov khoom ntawm lawv ntau qhov ntau thiab tsawg kom tau raws li qhov xav tau ntawm peb hnub Express CNC. kev pabcuam machining.

Tseem nrov tab sis teev tsawg dua yog tooj liab, tooj dag, phosphor bronze, me me steel, cuab yeej steel.Qee lub sij hawm, cov neeg siv khoom thov sepcial hlau.Yog tias peb tuaj yeem muab cov khoom siv thiab tshuab nws hauv tsev, peb yuav ua li ntawd, txwv tsis pub peb feem ntau ua haujlwm rau tus kws tshaj lij xaiv los ntawm peb lub network ntawm cov khw muag khoom uas ntseeg siab.Piv txwv li, cov khoom sib txawv xws li Inconel, Monel thiab Hastelloy yuav xav tau cov tswv yim tshwj xeeb thiab cov cuab yeej, yog li peb feem ntau outsource qhov no.

Hlau tuaj yeem ua tiav hauv ntau txoj kev sib txawv.Piv txwv li, txhuas feem ntau tuaj yeem ua kom pom tseeb anodised, hardcoat anodised, lossis xim dub lossis xim anodised.Qhov kev xaiv nyob ntawm seb qhov yuav tsum tau ua yog txhawm rau txhim kho qhov zoo nkauj lossis kev ua tau zoo (tshwj xeeb corrosive kuj lossis hnav tsis kam).

Stainless hlau yog inherently corrosion resistant tab sis tej zaum cov neeg muas zaub qhia meej ntxiv finishes.Electropolishing, piv txwv li, ua kom tiav cov khoom zoo nrog rau kev deburring thiab tshem tawm cov npoo ntawm qhov sib txawv.Ntawm qhov tod tes, yog tias qhov tawv tawv, hnav tsis kam lossis qaug zog yuav tsum tau txhim kho, ob qho tib si 304 thiab 316 stainless hlau tuaj yeem yog nitrocarburised lossis nitrided.

Cov hlau me me tau txais txiaj ntsig los ntawm tej zaum qhov kev xaiv dav tshaj plaws ntawm kev ua tiav.Cov kev xaiv muaj xws li kev pleev xim ntub dej, pleev xim rau electrophoretic, hmoov txheej, electroplating, tshuaj tua kab mob, electropolishing, hardening, titanium nitriding (TiN) txheej, nitrocarburising, thiab hlaws blasting, thiab lwm yam.

Tooj thiab tooj dag feem ntau tau teev tseg rau qhov chaw ua haujlwm, tsis tas yuav tsum tau ua tiav tom qab machining.Yog tias tsim nyog, txawm li cas los xij, cov khoom tuaj yeem polished manually, electropolished, electroplated, vapor blasted, lacquered los yog kho nrog tshuaj tua kab mob.

Cov kev ua tiav tau teev tseg saum toj no tsis yog tsuas yog muaj rau cov hlau thiab alloys.Peb ib txwm zoo siab los tham txog kev ua tiav nrog cov neeg siv khoom thiab peb sim pab txhua qhov chaw peb tuaj yeem ua tau.

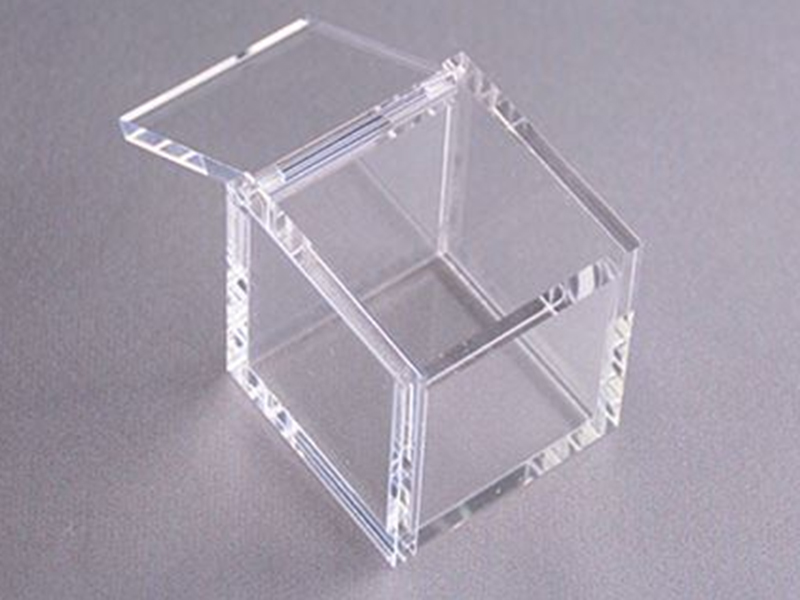

Ua tiav rau CNC Machined Plastic Prototype Parts

Raws li cov hlau sib cais, tag nrho cov khoom yas peb CNC tshuab yog qhov pib deburred, ntxuav thiab degreased tab sis, tom qab ntawd, cov kev xaiv saum npoo yuav txawv.

Raws li feem ntau ntawm cov neeg siv khoom thov CNC machined qauv yas qhov chaw hauv acetal (dub los yog ntuj) lossis acrylic, peb tuav ntau hom.cov khoom hauv Tshuag.Acetal tsis tuaj yeem txais cov khoom tiav ntxiv, yog li cov khoom feem ntau muab 'raws li machined'.

Acrylic, ua kom pom tseeb, feem ntau polished kom pom pob tshab.Qhov no tuaj yeem ua tiav manually nrog cov qib zoo ntawm cov abrasive, lossis nrog cov nplaim polishing.Raws li ib tus neeg thov, acrylic tuaj yeem pleev xim nrog cov xim acrylic lossis lub tshuab nqus tsev hlau kom ua tiav qhov zoo nkauj heev.

Qee qhov no yooj yim ua kom tiav dua li lwm tus, yog li koj tuaj yeem txais tos los tham txog cov ntaub ntawv thiab ua tiav nrog peb.Hais txog yas, peb tuaj yeem xuab zeb, prime thiab xim qhov chaw, polish lawv (manually los yog nplaim), electroless phaj los yog nqus metallise.Rau qee cov yas uas tsis muaj zog saum npoo av, tshwj xeeb nto npaj nrog primer lossis plasma kho yog tsim nyog.

Dimensional soj ntsuam ntawm CNC Machined Prototype Parts

Ib qho laj thawj vim li cas cov neeg siv khoom xaiv kom muaj cov qauv qauv CNC tshuab ntau dua li 3D luam tawm yog qhov tseeb dua.Peb qhov kev kam rau siab rau CNC machined qhov chaw yog ± 0.1mm, txawm hais tias qhov ntev yog ib txwm tuav kom nruj dua, ua raws li cov qauv, cov khoom siv, thiab geometry.Peb nruj me ntsis tshuaj xyuas qhov ntev, tau kawg, cov neeg siv khoom tuaj yeem nug txog cov yam ntxwv tshwj xeeb kuaj xyuas.

Feem ntau cov kev ntsuas tuaj yeem raug coj los ntawm tes callipers lossis micrometers tab sis peb lub tshuab ntsuas kev sib koom tes (CMM) yog qhov zoo tshaj plaws rau kev tshuaj xyuas ntau dua.Qhov no yuav siv sij hawm thiab tsis muaj nrog peb cov kev pab cuam CNC siab heev tab sis nws yog ceev dua xa cov khoom mus rau lwm tus neeg rau CMM tshuaj xyuas.Qhov tsuas yog qhov tshwj xeeb yog thaum yuav tsum tau ua kom tiav, tag nrho cov txheej txheem tshuaj xyuas CMM, lossis ib pawg ntawm cov khoom tau raug tshuab thiab yuav tsum tau kuaj xyuas 100 feem pua.

Kev xaiv los ua ke rau CNC Machined Prototype Parts

Ib qho laj thawj yog cov neeg siv khoom xaiv kom muaj cov qauv qauv CNC machined es tsis yog 3D luam tawm yog qhov tseeb dua.Kev kam rau siab rau CNC machined qhov chaw yog ± 0.1mm, txawm hais tias qhov ntev yog ib txwm tuav kom nruj dua, nyob ntawm seb cov khoom siv thiab cov duab geometry.Peb yuav nruj me ntsis tshuaj xyuas txhua qhov chaw ua ntej xa zaub mov, thiab cov neeg siv khoom tuaj yeem thov kom muaj cov yam ntxwv tshwj xeeb los kuaj xyuas ib yam.

Feem ntau cov kev ntsuas tuaj yeem raug coj los ntawm tes callipers lossis micrometers tab sis peb lub tshuab ntsuas kev sib koom tes (CMM) yog qhov zoo tshaj plaws rau kev tshuaj xyuas ntau dua.Nws yog nrawm dua li xa cov khoom mus rau lwm tus neeg sab nrauv rau CMM tshuaj xyuas.Qhov tsuas yog qhov tshwj xeeb yog thaum yuav tsum tau ua kom tiav, tag nrho cov txheej txheem tshuaj xyuas CMM, lossis ib pawg ntawm cov khoom tau raug tshuab thiab yuav tsum tau kuaj xyuas 100 feem pua.

Post lub sij hawm: Jun-30-2022