Txhaj Molding yog dab tsi?

Txhaj Moulding yog txheej txheem tsim khoom zoo nkauj thiab yooj yim uas tuaj yeem tsim cov duab sib txawv rau cov khoom siv thiab cov khoom siv.Txhaj tshuaj molding yog cov txheej txheem ntawm kev xaiv rau cov tuam txhab nrhiav los tsim cov khoom siv rov ua dua tshiab nrog cov txheej txheem nruj me ntsis.Txhaj Moulding kuj yog ib qho kev xaiv tsim khoom nrov rau kev ua haujlwm siab, tsis yog vim qhov zoo ib yam ntawm cov khoom siv yas, tab sis kuj yog tus nqi-ib-ib feem txo nrog ntau dua kev tsim khoom.

Tsis tas li ntawd, Huachen Precision muaj kev txhaj tshuaj molding ntau lawm uas khiav me me li 100 qhov chaw.Peb qhov kev pabcuam txhaj tshuaj molding tso cai rau koj kom yooj yim txav los ntawm prototyping mus rau qhov kawg ntawm cov khoom.

Rau cov kauj ruam rau Moulding

Txhaj tshuaj

Thaum ob daim hlau ntawm pwm yog clamped ua ke, kev txhaj tshuaj tuaj yeem pib.Cov yas, uas feem ntau yog nyob rau hauv daim ntawv ntawm granules los yog pellets, melted cia rau hauv ib tug ua kua tiav.Tom qab ntawd, cov kua tau txhaj rau hauv pwm.

Clamping

Txhaj pwm feem ntau yog ua nyob rau hauv ob, clamshell-style pieces.Nyob rau theem clamping, ob daim hlau ntawm cov pwm raug thawb tawm tsam ib leeg hauv lub tshuab xovxwm.

Txias

Nyob rau hauv lub caij txias, cov pwm yuav tsum tau muab tso rau ib leeg kom cov yas kub sab hauv tuaj yeem txias thiab khov rau hauv cov khoom siv uas tuaj yeem raug tshem tawm ntawm pwm.

Lub tsev

Nyob rau hauv lub tsev theem, cov yas melted puv tag nrho cov pwm.Lub siab yog siv ncaj qha rau cov pwm kom ntseeg tau tias cov kua puv txhua qhov kab noj hniav thiab cov khoom tuaj tawm zoo tib yam rau pwm.

Tshem tawm

Nrog cov pwm qhib, lub ejector bar yuav maj mam thawb cov khoom ruaj khov tawm ntawm qhov qhib pwm kab noj hniav.Tus neeg tsim khoom yuav tsum siv cov cutters kom tshem tawm cov khoom pov tseg thiab ua tiav cov khoom kawg rau cov neeg siv khoom.

Pwm Qhib

Hauv cov kauj ruam no, lub tshuab clamping yuav maj mam qhib ob feem ntawm cov pwm los ua kom muaj kev nyab xeeb thiab yooj yim tshem tawm ntawm cov khoom kawg.

Txhaj Molding Manufacturing Capabilities

| Peb Lub Tuam Txhab Sib Koom Tes Ua Haujlwm muab rau koj yooj yim nkag mus rau ntau lub peev xwm los ua haujlwm rau tag nrho koj cov haujlwm tsim khoom. | |

| Lub npe | Kev piav qhia |

| Ceev Tooling | Pwm nrog cov khoom siv hlau pheej yig nrog lub neej ntev txog 20,000 khiav.Machined feem ntau 2-3 lub lis piam. |

| Cov cuab yeej siv ntau lawm | Tsob ntoo tawv pwm, machined feem ntau 4-5 lub lis piam. |

| Ib Kab Kab Moulds | Pwm muaj tsuas yog ib kab noj hniav, tsim ib chav nyob rau ib qho kev khiav. |

| Pwm nrog Side-Action Cores | cores swb tawm ntawm ib feem ntawm sab ua ntej nws tawm ntawm pwm.Qhov no tso cai rau undercuts yuav molded. |

| Multi-Cavity Pwm | Ntau cov kab noj hniav zoo ib yam yog machined rau hauv cov cuab yeej pwm.Qhov no tso cai rau ntau qhov chaw los tsim ib qho kev txhaj tshuaj, txo cov nqi tsev. |

| Tsev Neeg Pwm | Ntau qhov chaw yog tsim los rau hauv tib lub cuab yeej pwm.Qhov no tso cai rau kom txo qis ntawm cov cuab yeej siv. |

| Ntxig Moulding | Inserts muab tso rau hauv pwm thiab molding tshwm sim nyob ib ncig ntawm lawv.Qhov no tso cai rau cov ntxig xws li helicoils tuaj yeem ua rau hauv koj tus qauv tsim. |

| Overmolding | Premade qhov chaw yog muab tso rau hauv pwm los pwm tshaj lawv.Qhov no tso cai rau kev txhaj tshuaj molding ntau yam. |

Qhov zoo ntawm Txhaj Molding

1.Excellent ntau lawm ceev rau huab hwm coj ntau lawm

2. Tsawg tus nqi ib feem thiab siab precision

3.Excellent nto finishes

4.Txoj kev siv zog zoo tshaj plaws

5.A ntau yam khoom siv xaiv

Txhaj Molding Plastic Parts Showcase

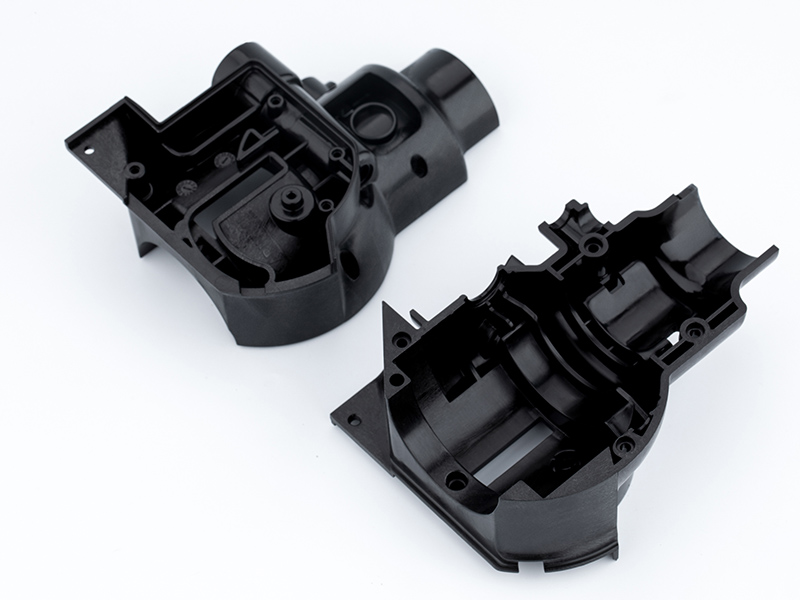

Kev cai Txhaj Molding Part

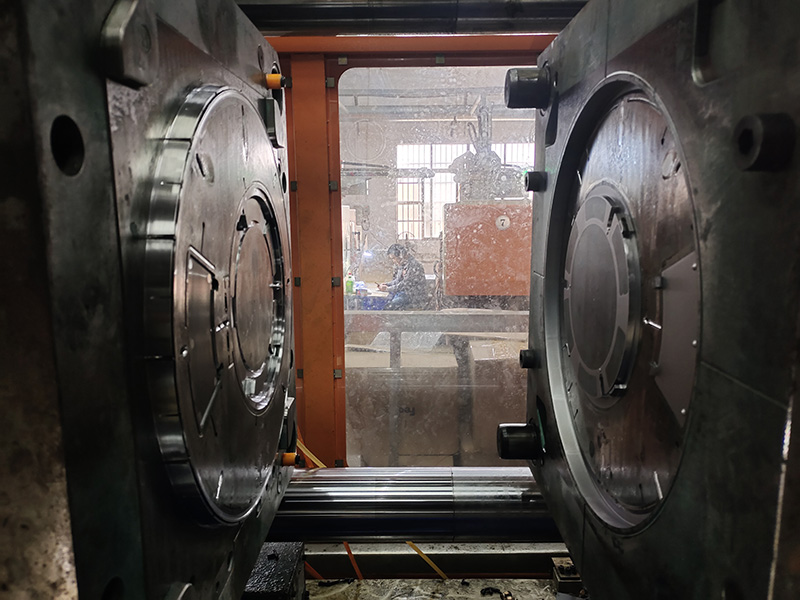

Exported Txhaj Mould

Moulding Yas Qhov Chaw

Txhaj Molding Dawb Qhov Chaw

Tsawg Volume Tooling