Vacuum Casting / Urethane Casting yog dab tsi?

Polyurethane nqus plua plav casting yog ib txoj hauv kev los ua cov qauv zoo lossis cov ntim tsawg ntawm cov khoom tsim los ntawm pheej yig silicone pwm.Cov ntawv luam ua nyob rau hauv txoj kev no qhia qhov nthuav dav zoo nkauj thiab kev ncaj ncees rau tus qauv qub.

Huachen Precision muab cov kev daws teeb meem ua tiav rau kev tsim cov qauv tswv thiab cov ntawv luam tawm raws li koj tus qauv CAD.

Peb tsis tsuas yog ua cov pwm zoo xwb tab sis peb kuj muab cov kab tag nrho ntawm cov kev pabcuam tiav nrog rau kev pleev xim, xuab zeb, pad luam ntawv thiab lwm yam.Peb yuav pab koj tsim qhov chaw rau cov chav ua yeeb yam zoo tshaj plaws, cov qauv kuaj engineering, kev sib tw crowdfunding thiab ntau dua.

Qhov zoo ntawm Vacuum Casting

Zoo heev rau Low Volumes

Nqus Casting yog qhov kev xaiv zoo tshaj plaws rau kev tsim cov ntim qis ntawm koj qhov hauv 1 txog 100 daim.Qhov nruab nrab silicone pwm yuav ua nyob ib ncig ntawm 12-20 qhov chaw, nyob ntawm sebcov khoom thiab geometric complexity, thiab cam khwb cia qhov chaw yog heev raug thiab heev repeatable.

Rapid Turnaround

Mos Silicone pwm cov cuab yeej tuaj yeem ua tau sai li 48 teev.Nyob ntawm seb qhov loj me, qhov nyuaj thiab ntim, Thawj Ntu Polyurethane nqus tsev casting tuaj yeem ua rau koj qhov chaw, tiav, nkoj, thiab xa tuaj sai li 7 hnub.

Cov Xim Xim Tus Kheej

Lub tshuab nqus tsev casting muaj peev xwm ua qhov zoo tshaj plaws nrog cov ntsiab lus zoo tshaj plaws.Cov xim zoo nkauj thiab pleev xim tiav yog ua tiav yam tsis muaj kev ua tiav tom qab.

Durability thiab muaj zog

Nqus Casting qhov chaw muaj zog dua li lawv cov 3D luam tawm counterparts.Tsis tas li ntawd, vim cov cam khwb cia urethane qhov chaw yog tsim los ntawm nruj thiab yoog raws cov qib plastics, lawv muaj qhov sib npaug, yog tias tsis muaj zog ntau dua, txheeb ze rau Txhaj molded qhov chaw.

Kev nqis peev qis qis

Silicone pwm yog qhov pheej yig dua thiab ua kom sai dua li cov cuab yeej siv rau kev txhaj tshuaj molding, ua rau tus nqi qis dua ntawm kev tsim khoom thiab tus nqi ib feem.Nws yog zoo meej rauengineering qauv, qauv, thiab prototypes sai rau ntau lawm.

Cov khoom sib txawv

Ntau hom polyurethane resins muaj nyob rau hauv casting, xws li roj hmab, silicone thiab overmolding.

Vacuum Casting Txheej txheem

Nws muaj peb kauj ruam los ua polyurethane nqus cam qhov chaw: ua tus qauv qauv, ua pwm thiab casting qhov chaw.

Kauj Ruam 1. Tus Qauv Qauv

Cov qauv yog 3D cov khoom ntawm koj cov qauv CAD.Lawv feem ntau yog ua los ntawm CNC machining lossis nrog 3D yas luam ntawv xws li SLA / SLS.Koj tuaj yeem muab koj tus kheej cov qauv lossis peb tuaj yeem ua rau koj.Cov qauv yuav tsum muaj peev xwm tiv taus cua sov mus rau 40 ° C.

Kauj Ruam 2. Ua Pwm

Casting pwm yog tsim los ntawm cov kua silicone.Qhov no silicone yog poured nyob ib ncig ntawm tus tswv qauv nyob rau hauv lub casting box, thiab ces tso cai rau kho nyob rau hauv lub qhov cub rau 16 teev.Thaum qhuav, cov pwm raug txiav qhib thiab tus tswv tshem tawm, tawm hauv qab lub qhov khoob khoob hauv qhov tsis zoo ntawm qhov qub.

Kauj Ruam 3. Casting Copys

Tam sim no koj xaiv cov resins tuaj yeem muab nchuav rau hauv qhov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob.Nws tseem tuaj yeem overmold nrog ob lossis ntau cov ntaub ntawv.Silicone pwm feem ntau yog zoo rau 20 los yog li cov ntawv luam ntawm tus tswv qauv.

Nqus Casting Materials

Pua pua ntawm casting polymers yog kev lag luam muaj nyob rau hauv reproduce ib tug conceivable hardness thiab nto zoo nkauj.Nws kuj tseem tuaj yeem ua rau qhov chaw uas muaj opaque, translucent lossis pob tshab kiag li nyob ntawm koj daim ntawv thov.Saib cov ntaub ntawv ntxiv ntawm cov ntaub ntawv muaj xws li hauv qab no:

Nqus Casting Materials suav nrog (Zoo li PU)

Pob tshab PU, Mos yas PU, ABS, PP, PE, Polycarbonate PU.Peb yuav khoom PU los ntawm Hei-Cast Company, Axson thiab BJB tuam txhab

Nqus Casting Polyurethanes Resins

| Khoom siv | Tus neeg muab khoom | Khoom siv simulation | Lub zog ntug dej hiav txwv | Flexion(PMA) | TC Max | Khoom piav qhia xim | Qhov zooQhov tsis zoo | Lub shrinkage |

| ABS HOM | ||||||||

| TIAB SA 8150 | Hei- Casting | ABS | 83sd ua | 1790 ib | 85 | Amber, Dawb thiab Dub | Kev Ua Phem Zoo | 1 |

| TIAB SA 4280 | Axson | ABS | 81sd ua | 2200 | 93 | Tsaus Amber | Kev Ua Phem Zoo | 1 |

| PX100 | Axson | PS kev | 74sd ua | 1500 | 70 | Dawb/Dub | Zoo tagnrho | 1 |

| POLYPRO HOM | ||||||||

| TIAB SA 5690 | Axson | PP | 75-83 : kuv | 600-1300 Nws | 70 | Dawb/Dub | Kev Ua Phem Zoo | 1 |

| COLORABLE ELASTOMER | ||||||||

| TIAB SA 8400 | Hei- Casting | Elastomer | 20-90 dr hab | / | / | Milky dawb/Dub | Zoo Khoov | 1 |

| t0387 ua | Hei- Casting | Elastomer | 30-90 dr hab | / | / | Ntshiab | Zoo Khoov | 1 |

| HIGH kub | ||||||||

| PX527 | Hei- Casting | PC | 85sd ua | 2254 ib | 105 | Dawb/Dub | Siab TC105 ° | 1 |

| PX223 HT | Hei- Casting | PS/ABS | 80sd ua | 2300 | 120 | Dub | Zoo tagnrho TC120 ° | 1 |

| UL-VO | ||||||||

| TIAB SA 8263 | Hei- Casting | ABS | 83sd ua | 1800 | 85 | Dawb | 94V0 nplaim Retarding | 1 |

| PX330 | Axson | Loaded ABS | 87sd ua | 3300 ib | 100 | Tawm Dawb | 0v 25 | 1 |

| TSHIAB | ||||||||

| PX522 HT | Axson | PMMA | 87sd ua | 2100 | 100 | Ntshiab | Xim TG100° | 0.996 ib |

| PX521 HT | Axson | PMMA | 87sd ua | 2200 | 100 | Ntshiab | Xim TG100° | 0.996 ib |

Nqus Casting Tolerances

Qhov ua tiav qhov ntev ntawm lub tshuab nqus tsev cam khwb cia yog nyob ntawm qhov tseeb ntawm tus qauv qauv, ib feem ntawm geometry thiab hom khoom siv casting.Feem ntau qhov shrinkage tus nqi ntawm 0.15% yog xav tau.

Ua tiav

Raws li tsim

Nqus casted qhov chaw yog ntxuav tom qab-casting thiab sab laug raws li manufactured.Txij li cov khoom siv polyurethane muaj cov qib siab ntawm smoothness thiab zoo nkauj tsos, tus txheej txheem tiav nyob rau hauv ib qho kev xaiv xim yog feem ntau rooj plaub rau casted qhov chaw.

Kev cai

Ib qho array ntawm kev cai tiav kuj muaj xws li los ntawm texturing thiab ntxig installation raws li kev xaiv tom qab ua tiav rau koj cov khoom casted.

Qhov feem ntau nto finishes yog:

· Glossy du tiav

· Smooth Matte tiav

· Rough finish

· Polished metallic tiav

· Structured tiav

Tshuaj pleev xim

Castings tuaj yeem pleev xim nrog ob peb lub tsheb-qib xim kom zoo nkauj thiab txhim khu nws lub ntsej muag zoo nkauj.Painting tej zaum yuav ntub painting los yog hmoov-txheej, txau los yog ci.

Silk Screen

Silk screening yog txheej txheem luam ntawv muaj rau koj lub tshuab nqus tsev casted.Nws suav nrog kev siv mesh los hloov tus cwj mem ntawm lub logo, ntawv nyeem, lossis cov duab kos rau thaj tsam ntawm koj qhov chaw.

Nqus Casting Parts Showcase

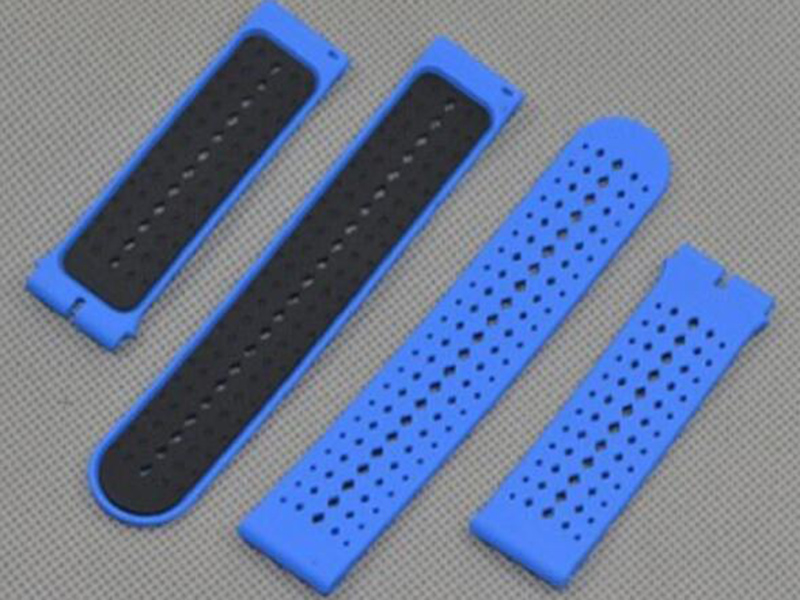

Small Batch Urethane Casting Parts

Overmold Parts

Custom Rubber Phone Plhaub

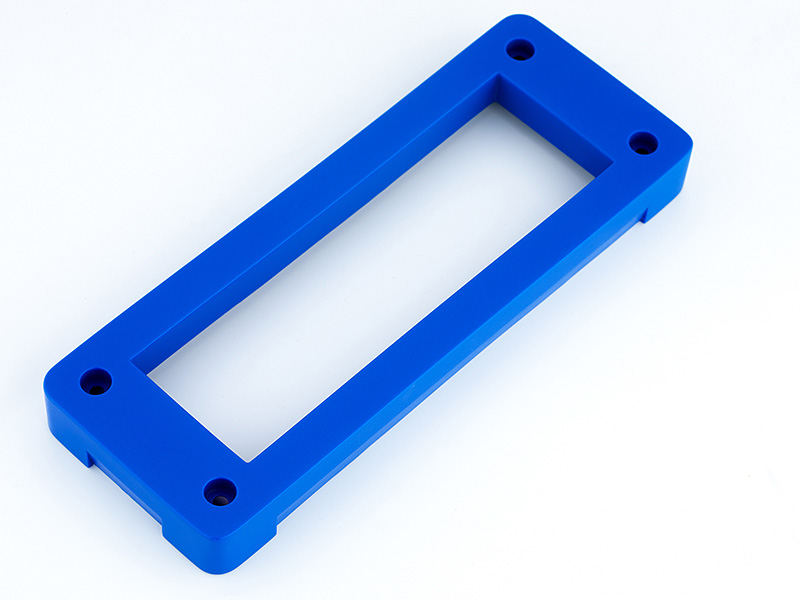

POM OEM pwm

Rubber Part