Hlau Tuag Casting yog dab tsi?

Tuag Casting yog hais txog cov txheej txheem ntawm cov khoom hlau tsim los ntawm pwm.Cov txheej txheem no tso cai rau cov khoom tsim los ntawm cov khoom loj loj nrog cov khoom zoo thiab rov ua dua.Cov txheej txheem pib los ntawm kev yuam cov hlau molten nyob rau hauv siab siab rau hauv cam khwb cia tuag.Cov tuag tuaj yeem muaj ib lossis ntau cov kab noj hniav (cov kab noj hniav yog cov pwm uas tsim cov duab).Thaum cov hlau khov kho (yuav nrawm li 20 vib nas this) ces qhov tuag qhib thiab txhaj tshuaj (qhov rooj, cov neeg khiav dej num thiab txhua qhov txuas nrog) raug tshem tawm thiab cov txheej txheem pib dua.Tom qab kev ua haujlwm tuag casting, qhov kev txhaj tshuaj feem ntau yog ua tiav ntxiv ntawm qhov txiav tuag qhov twg lub rooj vag, khiav thiab flash raug tshem tawm.Tom qab ntawd qhov tuaj yeem ua tiav ntxiv los ntawm vibratory deburring, txhaj tshuaj blasting, machining, painting, thiab lwm yam.

Qhov zoo ntawm Tuag Casting

Aluminium tuag casting yog cov txheej txheem ntau tshaj plaws los tsim cov khoom siv txhuas siv hauv ntau hom kev lag luam.Raws li txhuas muaj cov ntaub ntawv zoo heev flowability, corrosive kuj thiab siab dimension stability nrog complex qhov zoo li.

Aluminium tuag casting qhov yog siab txhua yam muaj zog, yooj yim rau cam khwb cia, thiab muaj tus nqi qis dua piv rau zinc lossis magnesium tuag casting qhov chaw.

Aluminium tuag casting qhov chaw muaj lub cev zoo heev uas tiv taus qhov kub thiab txias, uas ua rau aluminium casting tuaj yeem siv rau hauv tsheb, dav hlau, kho mob, thiab lwm yam khoom lag luam.

Tsib kauj ruam

Kauj Ruam 1. Khoom Melting

Txij li thaum txhuas muaj qhov melting siab heev (660.37 ° C) uas tsis tuaj yeem yaj hauv lub tshuab tuag casting ncaj qha.Qhov no yog vim li cas peb yuav tsum tau pre-melted nws nrog lub cub tawg uas txuas raulub tshuab tuag casting.

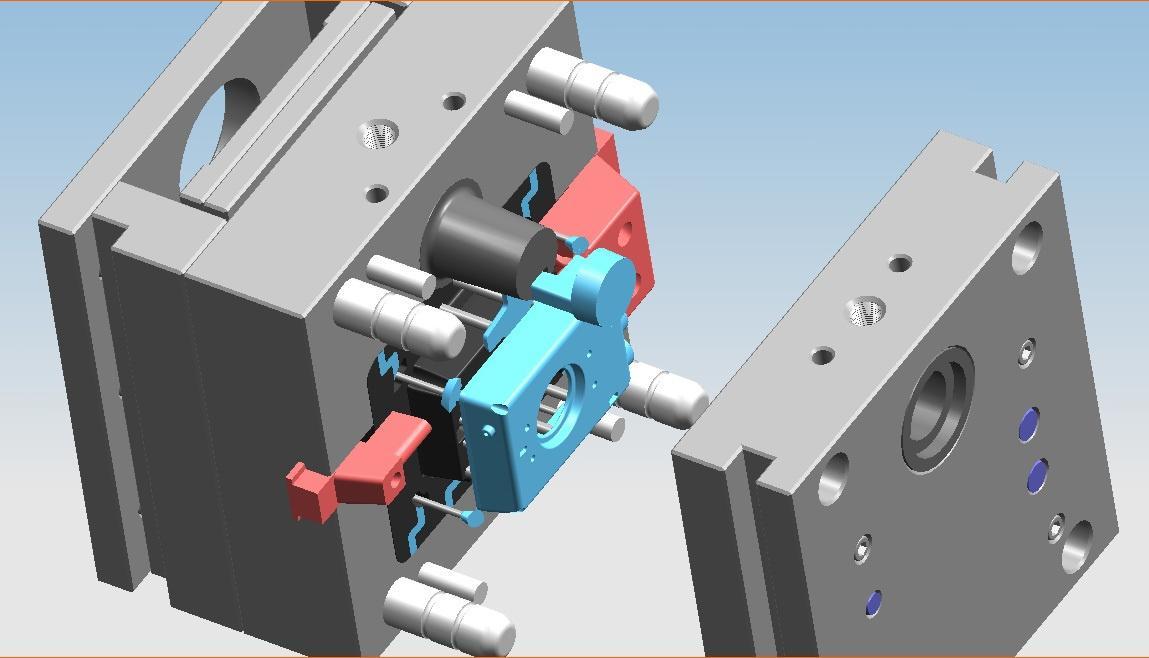

Kauj Ruam 2. Pwm Tool Mounting thiab Clamping

Nws yuav luag zoo ib yam li kev txhaj tshuaj molding, cov txheej txheem tuag casting kuj xav tau cov cuab yeej pwm rau txheej txheem casting.Yog li ntawd, peb yuav tsum tau mount lub tuag casting pwm cuab yeej ntawm ib tug txias tuag castingtshuab.

Kauj Ruam 3. Txhaj lossis Filling

Cov khoom molten yog hloov los ntawm lub cub tawg mus rau tuag casting tshuab los ntawm ib tug txav mus los ladle.Nyob rau theem no, cov khoom yuav raug nchuav thiab raug yuam mus rau hauv qhov tuag casting pwm kab noj hniav qhov twgcov khoom txias thiab solidifies kom tau cov khoom uas xav tau tuag casting.

Kauj ruam 4. Txias thiab Solidification

Tom qab cov cuab yeej tuag casting pwm yog tag nrho cov khoom molten, nws yuav siv sij hawm 10 ~ 50 vib nas this kom txias thiab solidify (nws nyob ntawm tus qauv thiab qhov loj).

Kauj Ruam 5. Ntu ejection

Thaum cov pwm qhib, cov khoom uas tau muab pov tseg yuav raug tshem tawm los ntawm ejection pins los ntawm cov cuab yeej tuag casting pwm.Tom qab ntawd cov khoom nyoos casted yog npaj txhij.

Tuag Casting Parts Showcase

Rapid Prototype Tooling Part

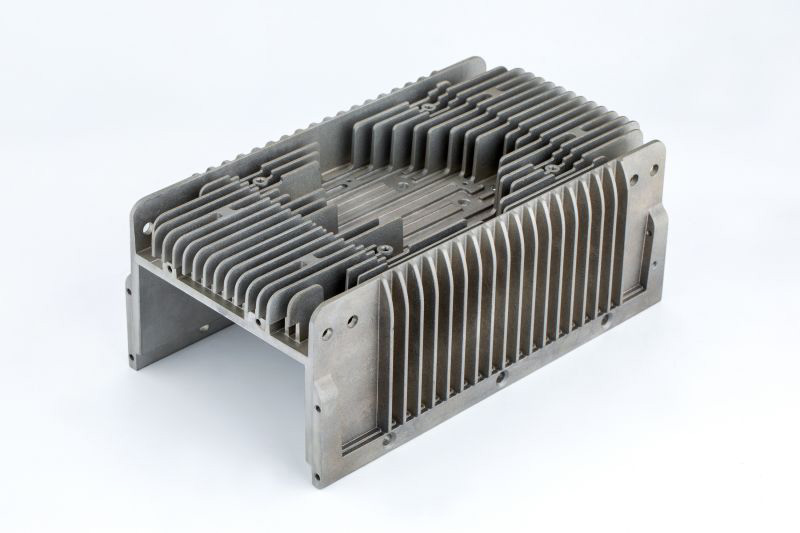

Loj Ntau Lawm Tuag Casting Parts

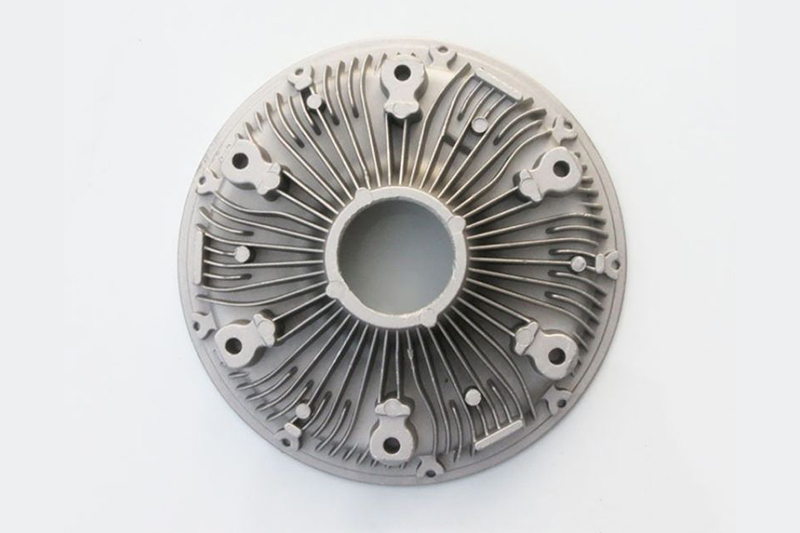

Kev Cai Tuag Casting Part

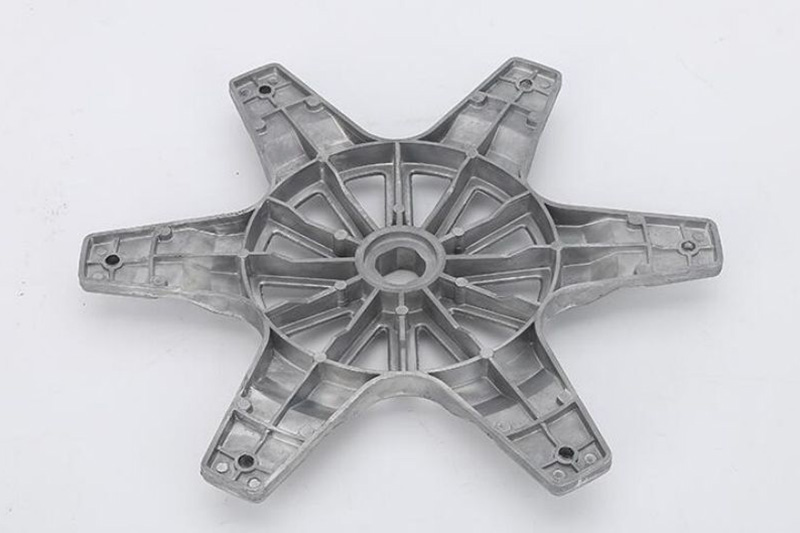

Tuag Casting Part Tsis Muaj Kev Kho Mob Finshing

Prototype Tooling Part