Muaj ntau txhiab cov ntaub ntawv nyob rau hauv kev ua lag luam, tab sis koj puas paub xaiv cov khoom tsim nyog?Thiab koj puas paub yuav ua li cas thiaj nrhiav tau cov khoom zoo tshaj plaws rau kojCNC prototype qhov chaw?Yog tias koj nyob hauv qhov xwm txheej nyuaj no,

koj yuav pom xaiv cov khoom tsim nyog rau koj cov khoom raug txwv los ntawm ntau yam.Lub hauv paus ntsiab lus tseem ceeb uas yuav tsum tau ua raws li yog: kev ua haujlwm ntawm cov khoom siv yuav tsum ua tau raws li ntau yam kev cai thiab cov kev cai ib puag ncig ntawm cov khoom.

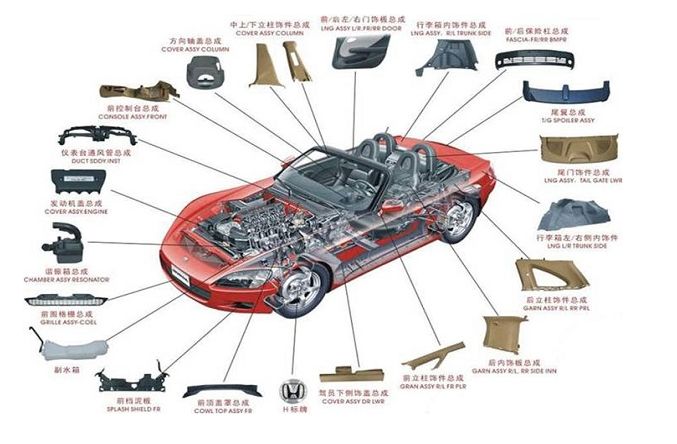

Thaum koj xaiv cov khoom siv rau cov khoom siv kho tshuab,CNC Prototyping Parts, Fast Prototyping, Hardware Prototyping, tshiab zog tsheb, koj tuaj yeem xav txog 4 yam hauv qab no:

1) Khoom Rigidity

Rigidity yog thawj qhov kev txiav txim siab thaum xaiv cov ntaub ntawv, vim hais tias cov khoom precision xav tau qee yam kev ruaj ntseg thiab hnav tsis kam hauv kev ua haujlwm, thiab kev nruj ntawm cov ntaub ntawv txiav txim siab qhov ua tau ntawm cov khoom tsim.Ntau rigidity txhais tau hais tias cov khoom yuav tsis tshua muaj deform nyob rau hauv sab nraud rog.Raws li cov yam ntxwv ntawm kev lag luam, # 45 steel thiab aluminium alloy feem ntau yog xaiv rau cov cuab yeej tsis tsim qauv;#45 steel thiab aluminium alloy kuj tseem siv ntau dua raukev cai qhov chaw machining;aluminium alloy feem ntau yog siv rauAutomotive Prototype tsim.

2) Cov khoom ruaj khov

Rau cov khoom siv nrog cov kev cai siab, yog tias nws tsis ruaj khov txaus, ntau yam deformation yuav tshwm sim tom qab sib dhos, lossis deformed dua hauv cov txheej txheem siv.Hauv luv luv, nrog kev hloov pauv ntawm qhov kub thiab txias, av noo thiab kev co thiab lwm qhov chaw nyob rau hauv tas li deformation, uas yog npau suav phem rau cov khoom.

3) Cov khoom 'machinable

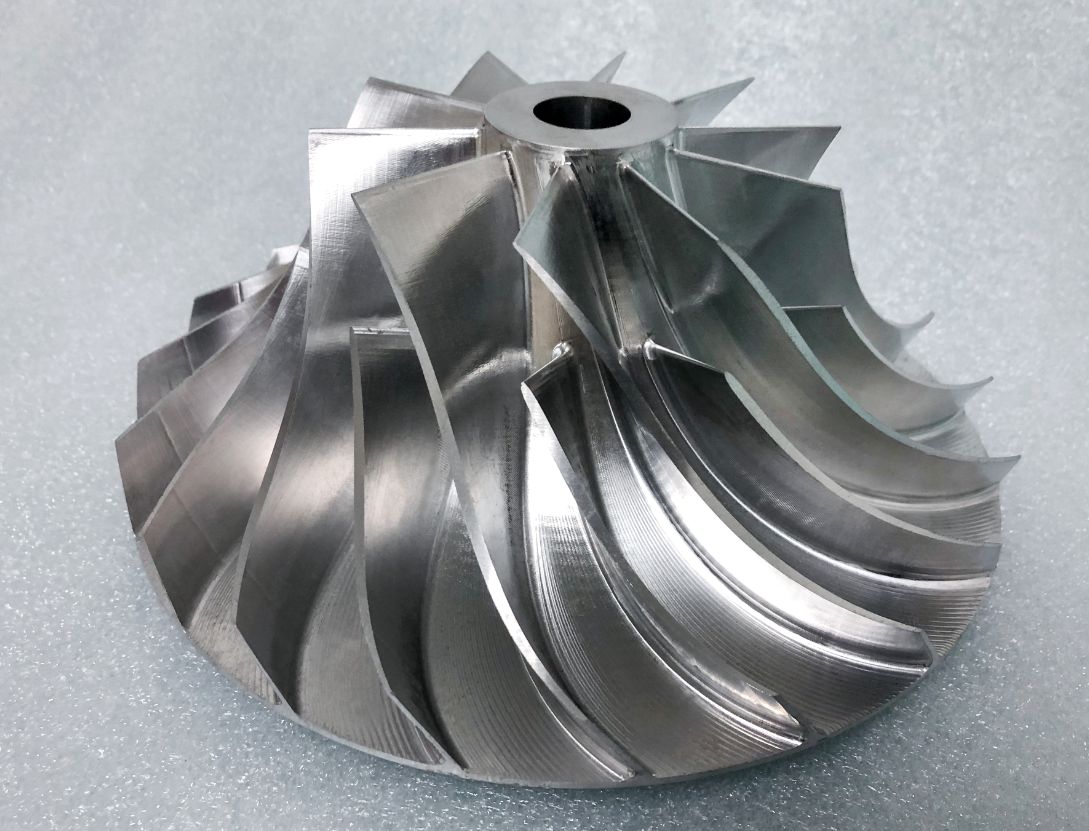

Cov cuab yeej machining ntawm cov ntaub ntawv txiav txim siab seb qhov twg yog qhov yooj yim rau tshuab lossis tsis.Piv nrogaluminium alloy prototype qhov chaw,

stainless hlau cov khoom muaj ib tug hardness ntau dua thiab yog ib qho nyuaj rau txheej txheem.Vim nws yog ib qho yooj yim ua rau cov cuab yeej hnav thaum ua.Piv txwv li, machining ib co qhov me me nyob rau hauv stainless hlau qhov chaw, tshwj xeeb tshaj yog threaded qhov, nws yog ib qho yooj yim mus ua txhaum lub drils thiab txiav cov cuab yeej, kuj yooj yim rau tawg cov ntsia hlau kais, uas yuav ua rau ib tug heev machining nqi.

4) Cov khoom siv

1. Tus nqi yog qhov tseem ceeb hauv kev xaiv cov khoom.Nyob rau hauv qhov xwm txheej ntawm kev loj hlob AI thev naus laus zis thiab lub zog tshiab nrov, yuav ua li cas xaiv cov khoom siv zoo tshaj plaws kom txuag tau tus nqi thiab txuag lub sijhawm nkag mus rau hauv kev ua lag luam uas dhau los ua kev sib tw!Piv txwv li, Titanium alloy muaj lub teeb yuag, lub zog tshwj xeeb thiab zoo corrosion kuj.Nws yog dav siv nyob rau hauvtshiab zog tsheb cavsystems thiab plays lub luag haujlwm tseem ceeb hauv kev txuag hluav taws xob thiab kev txo qis.Txawm tias superior zog ntawmtitanium alloy qhov chaw, lub ntsiab barrier uas coj mus rau nws dav siv nyob rau hauv lubtshiab zog automotive kev lag luamyog tus nqi siab.Koj tuaj yeem xaiv cov khoom pheej yig dua yog tias koj tsis tas yuav muaj.

Cov ntaub ntawv tsis raug, tag nrho hauv vain!Thov ua tib zoo xaiv koj cov khoom, Yog tias koj tsis paub yuav xaiv li cas, thov koj xav tiv tauj peb, peb nyob online txhua lub sijhawm, ua tsaug!

Lub sij hawm xa tuaj: Plaub Hlis-20-2023